NDT Training for Welders: How Inspection Skills Can Boost Your Career

At a Glance: If you’re a welder looking to expand your career options and increase your earning potential, adding nondestructive testing (NDT) skills to your toolbox could be your next smart move. NDT training opens doors to higher-paying positions, more diverse work environments, and greater job security across multiple industries.

The Connection Between Welding and NDT

Welders create the joints and structures that hold our industrial world together. NDT technicians verify that those welds meet industry standards without damaging the finished product. Because you already understand metal properties, joint configurations, and common weld defects, welders are ideal candidates for nondestructive testing careers. That foundation gives you a head start in NDT training programs.

The inspection side of the industry offers different advantages than pure welding work. While welders often work in physically demanding conditions and perform repetitive tasks, NDT technicians use specialized equipment to examine welds, structures, and components. The work requires attention to detail and technical knowledge rather than physical strength. According to a 2019 salary survey from Personnel Qualified for Nondestructive Testing, entry-level NDT inspectors averaged $74,997 annually.

Over time, welders with NDT experience can become Certified Welding Inspectors (CWI) and unlock even higher earning potential, with added job security and career advancement opportunities. Having a good understanding of NDT fundamentals guides welders toward this highly specialized career.

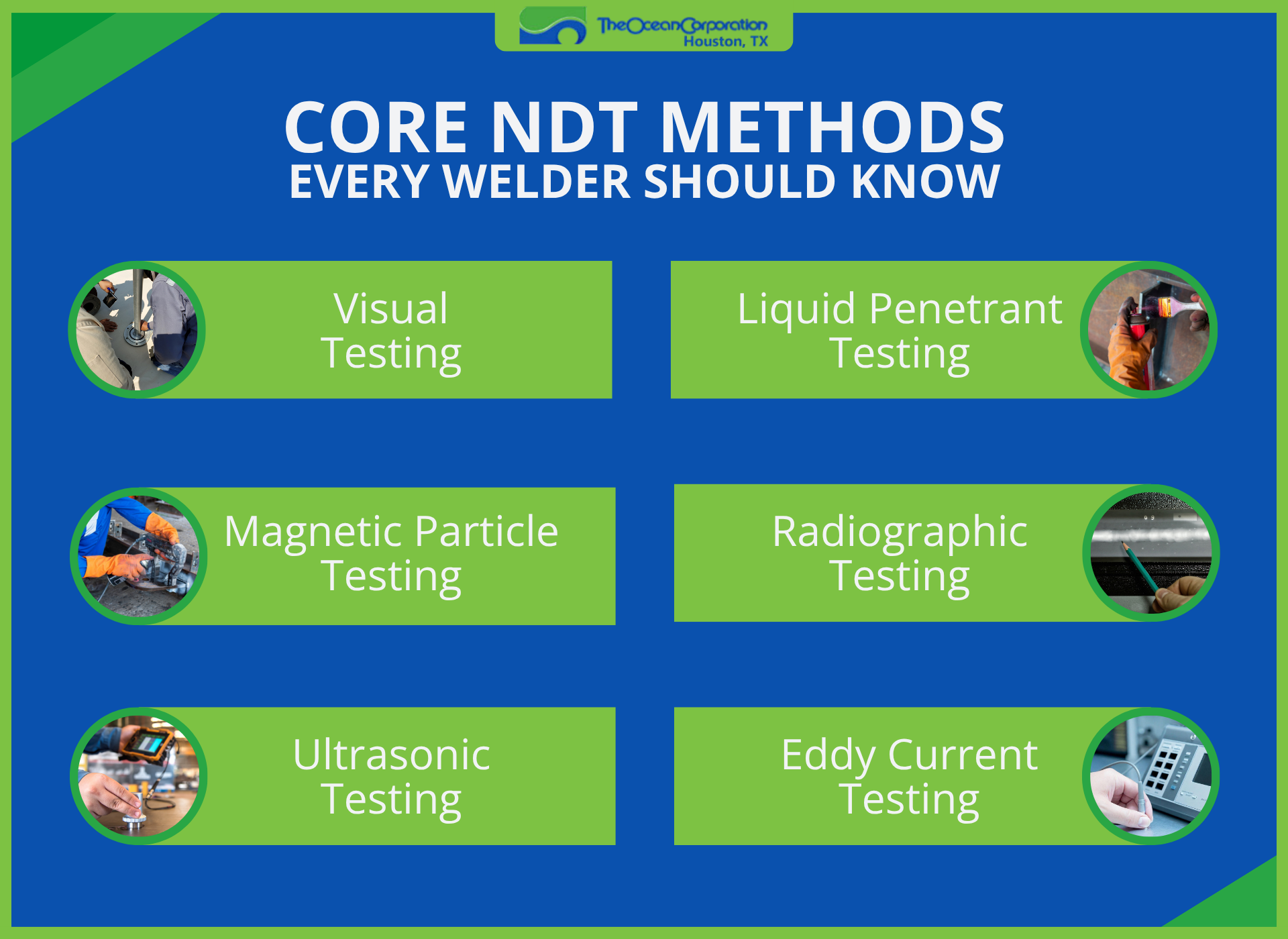

Core NDT Methods Every Welder Should Know

Professional NDT training commonly focuses on six core inspection methods, each serving specific purposes in quality control and safety verification. Knowing these methods helps you recognize which certification path matches your career goals.

Visual Testing (VT)

VT is the foundation of all NDT work. Every inspector starts here, learning to identify surface defects, measure dimensions, and document findings according to industry codes.

Liquid Penetrant Testing (PT)

PT reveals surface-breaking defects invisible to the naked eye. Inspectors apply liquid penetrant to surfaces, then use developers to draw out indications from cracks and other discontinuities. This method works on non-porous materials and requires minimal equipment, making it ideal for field applications.

Magnetic Particle Testing (MT)

MT uses magnetic fields to detect surface and near-surface defects in ferromagnetic materials. When you magnetize a part and apply iron particles, they cluster at discontinuities, revealing flaws. This method excels at finding defects in welds, castings, and forgings.

Radiographic Testing (RT)

RT employs X-rays or gamma rays to examine internal structures. Similar to medical X-rays, this method creates images showing internal defects, voids, and inclusions. Modern digital detector array technology has made radiographic inspection faster and often easier to interpret compared to traditional film. Radiation safety protocols are a major component of RT training.

Ultrasonic Testing (UT)

UT uses high-frequency sound waves to detect internal flaws and measure material thickness. The equipment sends sound pulses through materials and analyzes the echoes. This versatile method works on most materials and can detect defects deep within thick sections.

Eddy Current Testing (ET)

ET applies electromagnetic induction to detect surface and near-surface defects in conductive materials. This method excels at finding cracks in aerospace components and heat exchanger tubes.

What Makes Quality NDT Training Different

The best NDT programs focus on hands-on training rather than theory alone. At a proper training facility, you’ll spend most of your time working with actual equipment, practicing on real components, and learning from instructors with years of experience in the field.

Quality training organizations provide:

- Equipment matching what you’ll use in the field

- Real-world samples with actual defects

- Practice meeting industry standards

- Documentation and reporting procedures

- Code interpretation skills

- Safety protocols for each method

“I didn’t even know what non-destructive testing was till I got here. Ocean Corp gave me the foundation to accelerate my career,” says Tommy Ripper, now an NDT specialist and co-owner of his own company.

The Ocean Corporation, operating since 1969 as an industry leader in technical training, provides NDT education in all six common methods. Our Houston training facility spans 4.2 acres with dedicated NDT classrooms and full equipment suites. Most students complete their NDT course in less than 8 months.

The Certification Process: Building Your Credentials

NDT certification follows a structured path through different levels:

- Level I Technicians perform specific tests under supervision. They collect data and can identify discontinuities but don’t interpret results independently.

- Level II Technicians set up equipment, conduct tests, and interpret results according to codes and standards. This level brings more responsibility and higher pay.

- Level III Professionals develop procedures, train other inspectors, and make final determinations on accept/reject decisions. Reaching this level typically requires several years of documented experience.

The certification program includes:

- Classroom training covering theory and codes

- Hands-on learning with equipment

- Written examinations

- Practical application tests

- Vision requirements (near vision and color differentiation)

- Documentation of training hours

Each certification body maintains specific requirements. The American Society for Nondestructive Testing (ASNT) provides widely recognized certifications, while some industries require additional specialized credentials.

Career Paths and Industry Opportunities

NDT skills open doors across multiple sectors. Each industry values different method combinations and offers unique work environments.

- Aerospace Industry: Requires the highest precision standards. Inspectors examine aircraft components, engines, and structural elements. The work demands meticulous documentation and strict adherence to Federal Aviation Administration requirements.

- Oil and Gas Sector: Offers opportunities both onshore and offshore. Pipeline inspections, refinery maintenance, and platform work provide steady employment. The Gulf of Mexico, where 97% of US offshore oil production occurs, creates particularly strong demand.

- Power Generation: Nuclear, wind, and traditional power plants all need regular inspections. This sector values inspectors who can work with advanced equipment and maintain security clearances.

- Manufacturing: Production facilities need inspectors for quality control and preventive maintenance. The work stays consistent and often allows regular hours.

- Infrastructure: Bridge inspections, structural steel verification, and construction quality control keep inspectors busy nationwide. Government contracts often provide stable, long-term projects.

Financial Benefits of Adding NDT to Your Skill Set

Welders who add NDT certifications typically see immediate salary increases. The combination of welding knowledge and inspection capabilities makes you valuable to employers who need both skill sets. Contract work often pays premium rates, especially for inspectors willing to travel.

Brandon Ford, an NDT Level II certified in MT, PT, and RT, reflects on his career path:

“It’s definitely enabled me to do a lot of things that other people haven’t. I noticed a lot of people have to fight over positions and classes and things of that nature in order to get certs, whereas all of mine are already done. I’ve never really had a down period. I think I actually had a very smooth sailing career compared to most people.”

Travel opportunities can significantly boost earnings. Many inspectors work rotation schedules that cover travel expenses while providing extended time off between assignments. International work commands even higher rates for qualified professionals.

Where you train matters too. A Georgetown University study measuring what graduates actually earn compared to what they paid for training ranked The Ocean Corporation 9th out of 4,500 colleges, putting us in the top 0.2% nationally. That’s the kind of outcome data that matters when you’re weighing a career investment.

Getting Started: Choosing Your Training Path

Selecting the right training course requires research. Look for programs offering:

- Multiple certification methods in one program

- Actual equipment time, not just classroom lectures

- Instructors with field experience

- Job placement assistance

- Financial aid options

While online courses can supplement theoretical knowledge, NDT requires hands-on practice to develop proficiency. If you can’t commit to a fully in-person course, consider hybrid training. You need time with actual equipment to build confidence and competence.

Consider your current situation when planning training:

- Can you attend full-time or need evening classes?

- Will you need financial assistance?

- Can you complete an intensive program or need extended scheduling?

- Do you have specific industry targets requiring particular certifications?

Federal student aid programs and workforce development grants often cover NDT training costs. The American Society for Nondestructive Testing also offers scholarships specifically for students entering the field.

Making the Transition: From Welding to Inspection

The shift from welding to NDT doesn’t mean abandoning your welding background. Your understanding of welding processes, common defects, and fabrication standards provides valuable context for inspection work. You know what good welds should look like and understand how defects form.

Many professionals maintain both skill sets, performing welding and inspection work as projects require. This flexibility increases your value to employers and provides career security during industry fluctuations.

Starting your NDT career typically follows this progression:

- Complete formal training in chosen methods

- Pass certification examinations

- Gain field experience under Level II supervision

- Document your experience hours

- Advance to Level II certification

- Expand into additional methods as opportunities arise

The Future of NDT: Technology and Opportunities

The inspection industry continues evolving with technology. Digital radiography replaces film, phased array ultrasonics provides detailed imaging, and automated systems increase efficiency. Staying current with technological advances keeps you competitive.

New applications for NDT emerge regularly. Wind turbine inspections, composite material testing, and additive manufacturing quality control create fresh opportunities. New infrastructure and aging industrial facilities guarantee steady inspection demand for decades ahead.

Take Action on Your Career Growth

Adding NDT capabilities to your welding background positions you for long-term career success. The combination of fabrication knowledge and inspection skills makes you invaluable to employers across industries. With proper training, you can complete certifications and immediately increase your earning potential.

The Ocean Corporation provides complete NDT training in all six primary methods, with hands-on equipment time and experienced instructors guiding your development. Our Houston location offers proximity to Gulf Coast industries actively hiring certified inspectors. Contact our admissions team to discuss how NDT training can advance your welding career into inspection and quality assurance roles.

Frequently Asked Questions

What is NDT training for welders?

NDT training for welders teaches you how to use non destructive testing methods to inspect welds and base metal without cutting, grinding, or damaging the part. It builds on your existing welding experience and prepares you for NDT certification and inspection jobs.

Do I need welding experience before starting NDT training?

You can start nondestructive testing training with no welding background, but welders have a major advantage. If you already understand weld symbols, procedures, and common weld defects, you will move through NDT training faster and be more comfortable interpreting inspection results.

Which NDT methods are most useful for welders to learn first?

For weld inspection, the most common starting methods in NDT training are Visual Testing (VT), Liquid Penetrant Testing (PT), Magnetic Particle Testing (MT), and Ultrasonic Testing (UT). These NDT methods are heavily used on structural welds, pressure vessels, pipelines, and fabricated components.

What NDT jobs can I get after training and certification?

After completing NDT training and earning Level I or Level II certification, welders can move into inspection roles in oil and gas, power generation, aerospace, manufacturing, and infrastructure.

How much can I earn with NDT training compared to welding alone?

NDT training often leads to higher annual income than welding alone because certified NDT technicians are in demand for inspection and quality assurance work. Welders with an NDT certification can qualify for higher rates, travel positions, and rotation schedules in high-paying industries.

Is online NDT training enough to start a career?

Online NDT courses are helpful for theory, but they are not enough by themselves. To qualify for NDT certification, you need hands-on training with inspection equipment. Consider a hybrid course if online learning works best for you.

How do I choose the right NDT training program as a welder?

Look for NDT training that offers multiple methods, experienced instructors, real lab time, and help with NDT certification and job placement. Ask about class size, equipment, program length, and how the school tracks your training and experience hours for future certification exams.

About The Ocean Corporation

Since 1969, The Ocean Corporation has trained commercial divers who work across offshore energy, ship repair, maritime infrastructure, and aerospace support. We’re the only U.S. school issuing IMCA international diving certifications, and we provide lifetime career services—not just initial placement. Our 30-week programs run five hours daily, allowing students to work part-time during training.

Programs are eligible for GI Bill benefits, Title IV federal aid, and state grants for those who qualify. Located in Houston, Texas, the heart of the Gulf Coast industrial corridor.

Compliance Note

Earnings vary based on employer, location, qualifications, and project type. Program length, curriculum content, and outcomes are subject to change. Career placement services assist graduates in finding employment but do not guarantee job placement or specific salary outcomes.